The following guidelines are general indications and serve as recommendations for the proper maintenance of integral polyurethane. To best preserve the surfaces, it is recommended to clean regularly with a soft, dry cloth or one slightly dampened with water. If necessary, neutral and mild detergents may be used, avoiding abrasive products, solvents, or harsh sponges that could damage the surface finish. It is important to dry thoroughly after cleaning to prevent any moisture buildup. Additionally, it is advisable not to expose the material to direct heat sources or intense sunlight for prolonged periods, in order to preserve its color and original characteristics. These instructions are intended as a general guide; for further details, it is always preferable to refer to the product’s technical documentation or contact the company directly.

.png)

Plastics

Plastics represent, for Desalto, a material used in the production of many chairs in the collection. These materials offer versatile solutions, capable of combining aesthetics with technical performance. Within the Desalto framework, the use of polypropylene and integral polyurethane reflects a design philosophy that values formal simplicity, production efficiency, and material consistency.

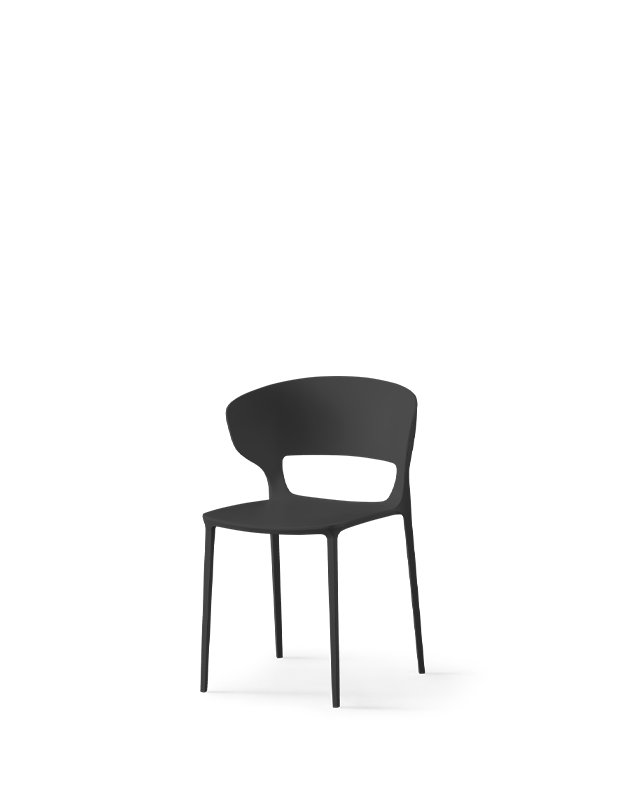

Integral polyurethane represents a technical and design solution that combines structural function and aesthetics in a single material. It is a differentiated-density foam polyurethane obtained through molding, which gives Desalto’s Koki chair its distinctive formal identity. In-mold coloring allows for uniform and compact surfaces that are durable over time and do not require additional surface finishes.

This material is distinguished by its high resistance to wear and impact, ease of cleaning, and good color stability. Its composition provides both lightness and strength, essential characteristics for daily use in both residential and contract environments. The combination of technical properties and expressive possibilities makes integral polyurethane a functional and contemporary material, perfectly aligned with Desalto’s design philosophy.

Polypropylene is a versatile and durable material, ideal for the production of seats and backs for products such as Sand and Ply, as well as for the full construction of chairs like Riga. This thermoplastic polymer, processed through injection molding, combines lightness and strength, allowing for the creation of ergonomic shapes and clean lines without compromising solidity and durability. Its smooth and compact surface ensures a uniform aesthetic and pleasant tactile experience, while the variety of colors achievable directly in the mold provides color consistency and expressive freedom.

Technical Area

Chairs made entirely of monobloc polypropylene represent a technical excellence of Desalto. The monolithic structure provides exceptional resistance to impacts, deformation, and continuous stress, ensuring extreme longevity. Polypropylene is self-supporting, requiring no additional frame to hold seat and backrest, simplifying production and reducing stress points. These features make it ideal for outdoor use, as the material resists moisture, temperature fluctuations, and UV exposure, maintaining shape and color over time. The combination of lightness, ergonomics, and durability makes Desalto’s monobloc chairs highly versatile and technically advanced.

Desalto’s Riga chairs exemplify sustainability applied to industrial design. The polypropylene used incorporates 30% recycled material from controlled industrial recirculation processes, significantly reducing environmental impact. This approach combines aesthetics, lightness, and material strength, ensuring durability and resistance typical of polypropylene, while maintaining eco-sustainability. The recycled content does not compromise mechanical performance: the seat remains self-supporting, resistant to impact and daily stresses in both residential and contract environments.

*Note: White Riga chairs are excluded, as recycling does not allow uniform color consistency in white.

Desalto’s Koki chair uses integral polyurethane for its seat-back structure, a high-performance technical material. The foam ensures immediate comfort and ergonomic support, while the color is added directly in the mold during injection, guaranteeing uniformity and superior aesthetic quality. The polyurethane surrounds an internal metal frame manufactured in Desalto’s workshop, creating a perfect balance between stability and lightness. This process produces compact, durable surfaces that require no additional finishes, reducing maintenance and preserving the original appearance over years of use.

Desalto’s integral polyurethane is engineered with differentiated density to provide both comfort and structural support. The denser inner core ensures stability and resistance to stress, while softer zones offer ergonomic cushioning. This solution combines lightness, durability, and ergonomic performance in a single material without additional components. The custom-calibrated density also maintains the seat’s shape over time, ensuring that comfort, elasticity, and performance are preserved even under intensive or prolonged use.

.jpg)

.png)

.jpg)